OSMOTEC holds extensive technical and project management capabilities to undertake most engineering projects for our customers. This is supplemented by Follow up O&M to enable guarantee of technical and financial performance, and minimum life cycle costs. On this page, you will find more about our

projects

and References

OSMOTEC Projects

Within our core fields of water, energy and waste, OSMOTEC design and build projects of any magnitude, to meet strict operational, environmental, and legislative requirements. These projects could be at the request of our customers or recommended by us and agreed by our customers for efficiency/improvement purposes. Projects are backed by OSMOTEC guarantee for operational and financial performance. Where appropriate, OSMOTEC may also provide the finance for the project.

For our Operation and Maintenance customers, we provide project services for a much wider range of applications, as usually required on an industrial site, from office extensions or refurbishments to road re-surfacing, factory moves and much more.

Key elements of our approach:

Design and Build by OSMOTEC

- Specialist teams define the process concept in collaboration with Customer.

- Upstream measures to minimise downstream cost.

- Mobilisation of technical specialists for each discipline to determine the most effective process.

- Process design, considering operating costs, to minimise total cost of ownership.

- Assessment of different operational and green options.

- Optimal integration of services and operational parameters for maximum efficiencies and minimum environmental impact

Post installation O&M by OSMOTEC

- OSMOTEC’s core competence

- Guaranteed results: SLAs / KPIs

- HSE and other regulatory compliance under all circumstances

- Reliability and accountability

- Flexibility for ongoing adjustment to business needs

- Reporting

OSMOTEC'S REFERENCES

- Client: BGC

- Duration: 4 months

- Capacity: 72 MLD

- location: Basra, Iraq

- Application: Desalination Plant

- Process Feed: River Water

- Standard: EU and AU/NZ

- Technology: Ultrafiltration (UF) + Reverse Osmosis (RO)

- Service: Feasibility Study and Technology Selection

- Client: SDC

- Duration: 6 months

- Capacity: 120,000 litre per day

- location: Qazvin, Iran

- Application: Demineralised water

- Process Feed: Bore Water

- Standard: US and EU

- Technology: Low Pressure/low fouling Reverse Osmosis

- Service: Design, Build and Installed

- Worth: US$ 38,000

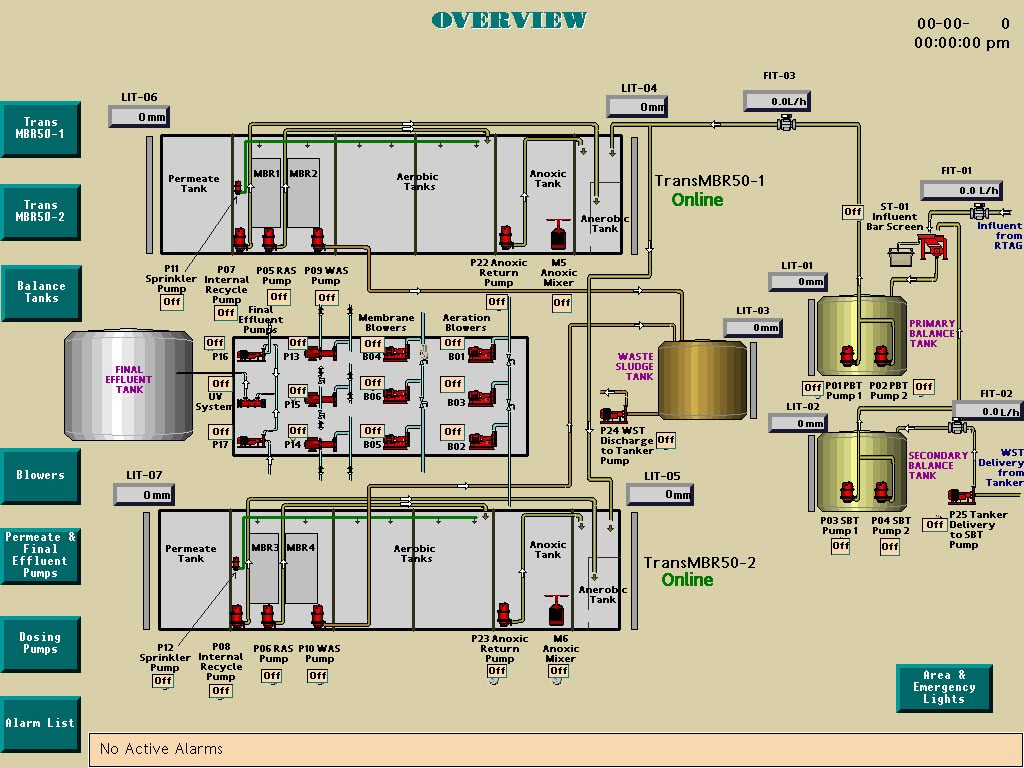

- Client: KJM

- Duration: 6 month

- Capacity: 130 QMD

- location: Queensland, Australia

- Application: Wastewater Treatment Plant

- Process Feed: Sewage (Camp)

- Standard: AU/NZ

- Technology: Chemical Free MBR

- Service: Design, Build, Install

- Worth: $280,000

- Client: KJM for Origin Energy

- Duration: 12 months

- Capacity: 65,000 litre/day

- location: Queensland, Australia

- Application: Sewage Treatment Plant

- Process Feed: Municipal Wastewater Stream

- Standard: AU/NZ

- Technology: Low fouling Membrane Bio Reactor(MBR), chemical free backwash

- Service: Engineering, Procurement, Construction, Installation and operation

- Worth: — US$ 285,000

- Client: WP

- Duration: 3 months

- Capacity: 130 MLD

- location: South East region of Queensland in Australia

- Application: Water Recycling Plant

- Process Feed: Municipal Wastewater Stream

- Standard: AU/NZ

- Technology: Microfiltration (MF) + Reverse Osmosis (RO)

- Service: Pilot Plant design Investigation

- Client: SBG & WP

- Duration: 4 months

- Capacity: 850 MLD

- location: Yanbu, Saudi Arabia

- Application: Seawater Desalination Plant

- Process Feed: Seawater

- Standard: US/EU/AU

- Technology: Multi Stage Flash (MSF) + Reverse Osmosis (RO)

- Service: Engineering, Assessment of treatment options

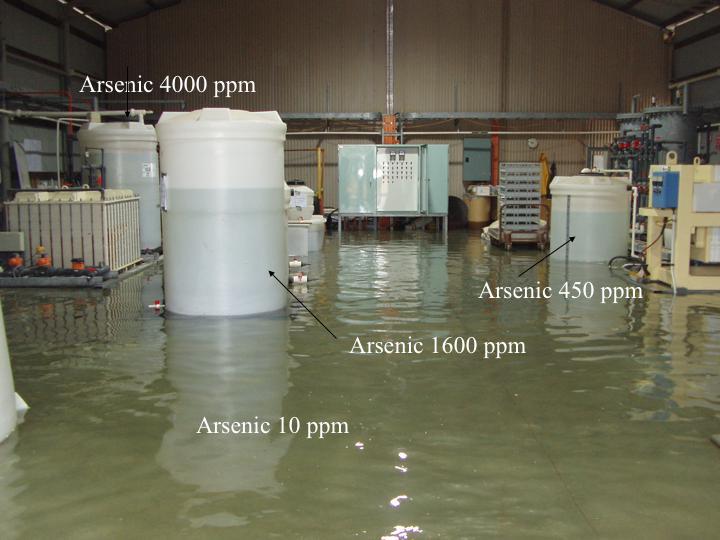

- Client: MIT Perth

- Duration: 24 month

- Capacity: 50 QMD

- location: Perth, Australia

- Application: Arsenic Removal Plant

- Process Feed: High Contaminated Water by Arsenic

- Standard: AU/NZ

- Technology: Ion Exchange, RO, Legand & Ion Exchange Membrane

- Service: Engineering, Design and build. R&D project

- Client: KJM for Hutchinson

- Duration: 12 months

- Capacity: 65,000 litre/day

- location: Queensland, Australia

- Application: Sewage Treatment Plant

- Process Feed: Municipal Wastewater Stream

- Standard: AU/NZ

- Technology: Low fouling Membrane Bio Reactor(MBR), chemical free backwash

- Service: Engineering, Procurement, Construction, Installation and operation

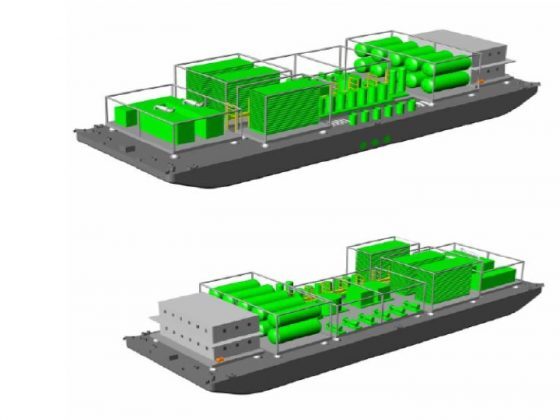

- Client: WP

- Duration: 6 month

- Capacity: 20 MLD

- location: Brisbane, Australia

- Application: Mobile Desalination Plant

- Process Feed: Salty River Water

- Standard: AU/NZ

- Technology: Micro Filtration (MF) + Reverse Osmosis (RO)

- Service: Engineering, infrastructure design across all disciplines

- Client: WP

- Duration: 12 month

- Capacity: 800 QMD

- location: Western Australia

- Application: Effluent

- Process Feed: Industrial MEK Influent

- Standard: AU/NZ

- Technology: CPI, MPPE & MBR

- Service: Review Detail Design and HAZOP

- Client: KJM for Rio Tinto

- Duration: 12 month

- Capacity: 130 QMD

- location: Western, Australia

- Application: Wastewater Treatment Plant

- Process Feed: Industrial Wastewater

- Standard: AU/NZ

- Technology: Membrane Bioreactor (MBR)

- Service: Project management, Design and Construction

- Client: KJM Industrial Camp

- Duration: 36 month

- Capacity: 325 QMD

- location: Queensland, Australia

- Application: Wastewater Treatment Plant

- Process Feed: Camp Wastewater

- Standard: AU/NZ

- Technology: Membrane Bioreactor (MBR)

- Service: Design, Commissioning and optimization